Dross only furnace

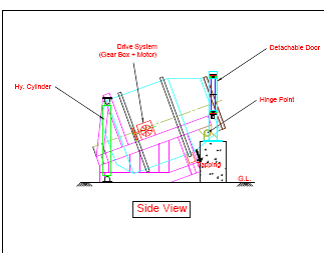

Hot dross from the furnace is collected in to a pan. The pan is shifted to dross processing machine by forklift/crane. Dross processing machine is a modified version of Universal Tilting Rotary Furnace. The major difference is that the door of the furnace is completely flush with the furnace and the door rotates with the furnace.

When all the dross is charged in to the furnace. The furnace door is attached with the furnace body and is detached with the door Colum. The furnace is rotated at a high speed which separate liquid aluminum metal from oxide. After the rotation the furnace tap hole which is located at the front end is open and liquid aluminum is tapped out by tilting the furnace upward. When all liquid metal is removed, the furnace is moved back to its original position and the door is removed from the furnace. Now all residual oxide with minimum amount of trace aluminum is collected in a pan for disposal .

Technical details

| Diameter of the main shell | 1800 mm |

| Furnace opening size | 900 mm |

| Length of the furnace shell | 2500 mm |

| Furnace frame | made out of 200 mm box structure |

| Supporting roller | 300 mm diameter hardened steel Roller with spherical roller bearing |

| Hydraulic cylinder | 1400 mm stroke single acting cylinder With 80 mm diameter Piston rod, Pivoted at both the end |

| Furnace drive | Through5 HP VF drive motor along With reduction gear box |

| Drive ring | Made out of hardened drive roller Attached to the drive ring |

| Furnace refractory | 10 mm thick cera wool paper followed By 150 mm insulation castable than 115 mm of 60% alumina brick |

| Power pack | A 2 HP power pack with solenoid valve Is provided for the action of hydraulic Cylinder. |

| Furnace door | Low density insulation castable door. The opening and closing of door is Manually. Extra two hole are provided With SS flapper, one for extra air Supply. Door is detachable from the door Column and is attached to furnace main Body. |

| Control panel | A control desk is provided along with the Furnace to operate the furnace via Remote operation and will have the Following equipment

|

The complete furnace is fabricated at our site with refractory lining. The trial of the furnace is carried out at our factory and testing of a functionality of every system. The total erection time at site is very less since the furnace is dispatched with refractory lining.