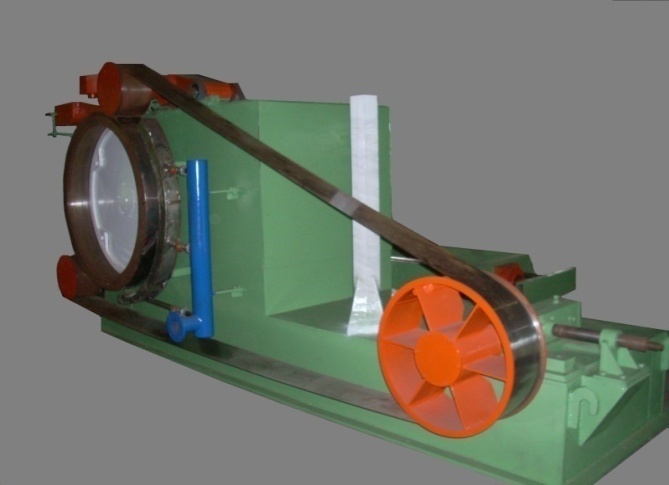

Net Shape Narrow Strip Caster

TECHNICAL SPECIFFICATIONS

The equipment consist of steel ring mold different diameter and having a cross section area varying from 300 x20 to 100 x 20 or other thickness is also available as per the requirement of customer . The top off the mold is covered with endless steel belt pressed against the mold with the help of belt pressing roll. Two rows of adjustable type SS nozzles are provided for the cooling of in-ner mold wall. Segment type outer spray with SS nozzles is provided for belt cooling. Metal Tundish with ceramic tip is provided for metal feed in to the mold .guide rollers along with floating guide is provided for the support and guide of strip. The drive to the caster is with drive coupled through double stage reduction gear box. The caster can operate with max speed of 2 rpm and min speed of 0.5 rpm.

OPERATION

The operation of strip caster is simple. It requires very less man power and it produces continuous strip from 100 to 300 mm width, 16 to 24 mm thickness of consistent quality. The temperature of strip so produced is nearly 450 degree centigrade close to hot rolling temperature and can be fed directly to hot rolling mill for the thickness reduction. Continuous casting and hot rolling operation can be performed simultaneously. The output is very high and of consistent quality. The percentage yield is also very high compared to book mold process as there is no end wastage. The product has very fine grain size as the rate of cooling is high. The deep drawing properties are better than conventional book mold process.