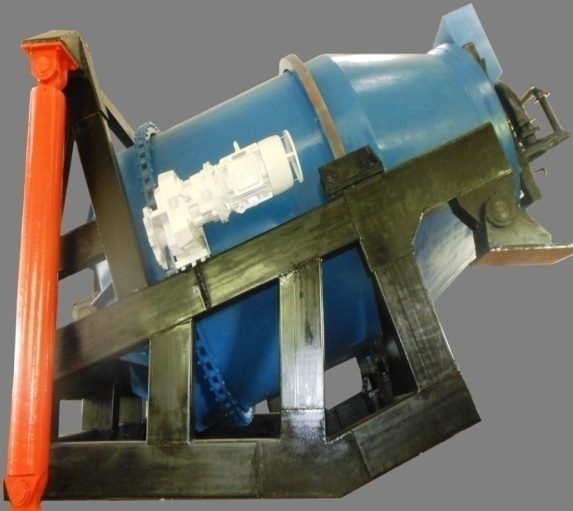

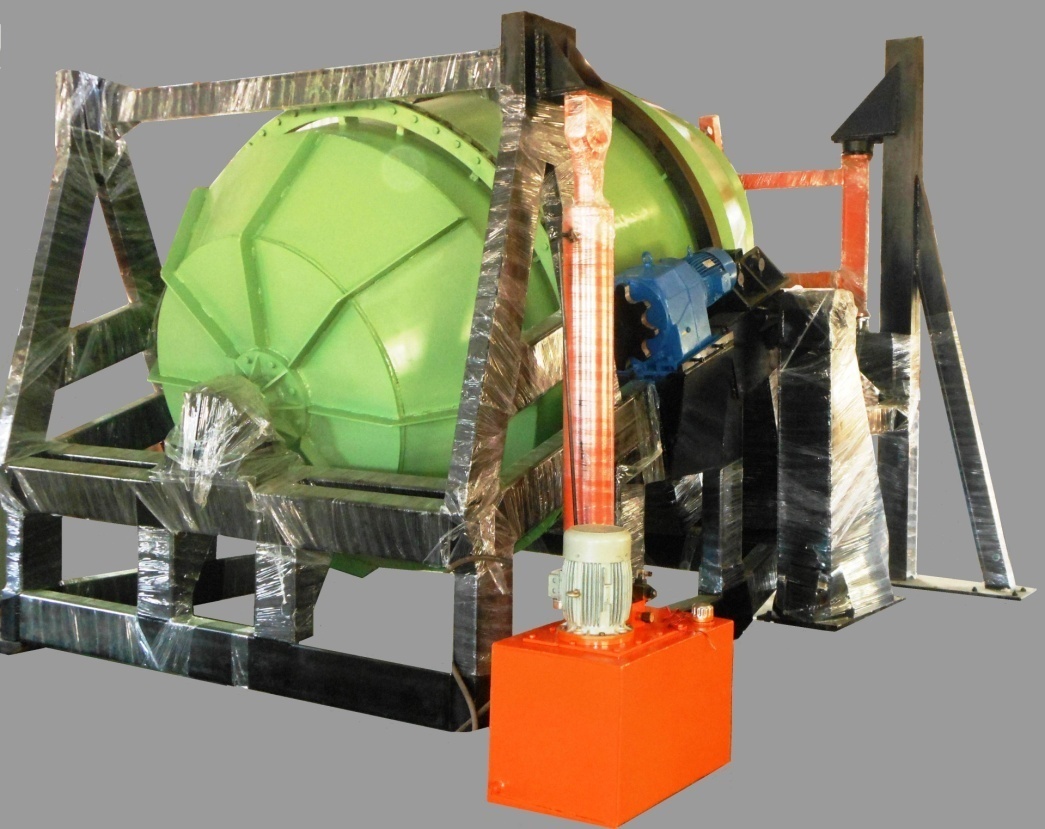

Universal Tilting Rotary Furnace

The Universal Tilting Rotary Furnace or simply Tilting Rotary Furnace is a rotating closed-well furnace. It combines the advantages of Rotary furnace, Revs furnace and Dry hearth furnace in a single unit.

A significant advantage claimed for the UTRF is that it can be both rotated and tilted. First of all the aluminum scrap is loaded in to the furnace with the smelting salt and the furnace is locked shut. By firing the burner that is mounted on the door, the material is heated with the help of oil/gas burner until it reaches melting point. Heating up is considerably faster due to horse shoe flame design. Due to high rate of heating oil consumption as well as melt loss is very less compared to other furnaces. The overall advantages of UTRF is

- Reduced amount of salt flux requirement for melting

- Improved working condition

- Different types of scrap can be processed in a single unit

- Homogeneous charge resulting in high quality material

- Self cleaning lining

- Offering low energy consumption and high thermal yield. It can reduce oil consumption by almost 30 % compared to traditional melting furnace.

- Ensuring faster melt rate, 2 times higher than traditional furnace.

- Higher yield of material