Thermal Chip Drier

Functional Description

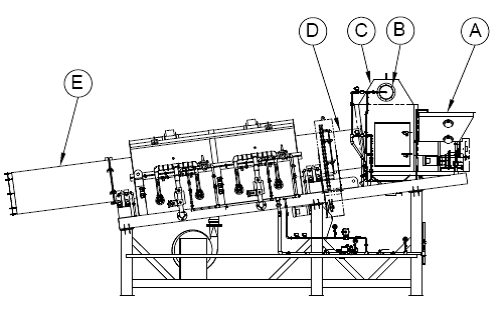

Chips from machining operations are fed into the screw feeder hopper (A). The screw feeder feeds the chips into the rotary hearth (D) at a constant rate. In the rotary hearth, the chips are typically heated to a set point temperature between 800 and 900°F to vaporize the water and oil. Products inside the rotary hearth (D) are indirectly heated. Natural gas fired burners/furnace oil burner to heat the rotary hearth from the outside. These burners are fired into a cavity between the outside of the rotary hearth and in-side of the furnace shell refractory. There is no direct flame impingement on the chips or extreme temperatures that could result in surface oxidation of the chips.

An induced draft fan draws room air into the discharge end of the rotary hearth. This air flows through the rotary hearth in the opposite direction (counter-flow)to the flow of chips. This air removes the water and oil.

Vapors, smoke and dust particles that are generated in the rotary hearth. The exhaust gases, smoke and dust particles are collected in the smoke hood (C) and exit to the pollution control system at point (B) on the smoke hood. Heavy hydrocarbon molecules will be ignited and oxidized in the rotary hearth.

If the temperature in the rotary hearth exceeds set point, cooling air is auto-matically introduced to cool the outside of the rotary hearth. If an excessive amount of hydrocarbons or other combustibles are introduced with the chips into the rotary hearth, water sprays in the smoke hood (C) are automatically initiated to quench the fire.

Dried chips exit the rotary hearth (D) and enter the rotary cooling section (E), where the chips are cascaded through the induced draft, room temperature air, and exit at approximately 300-400°F.